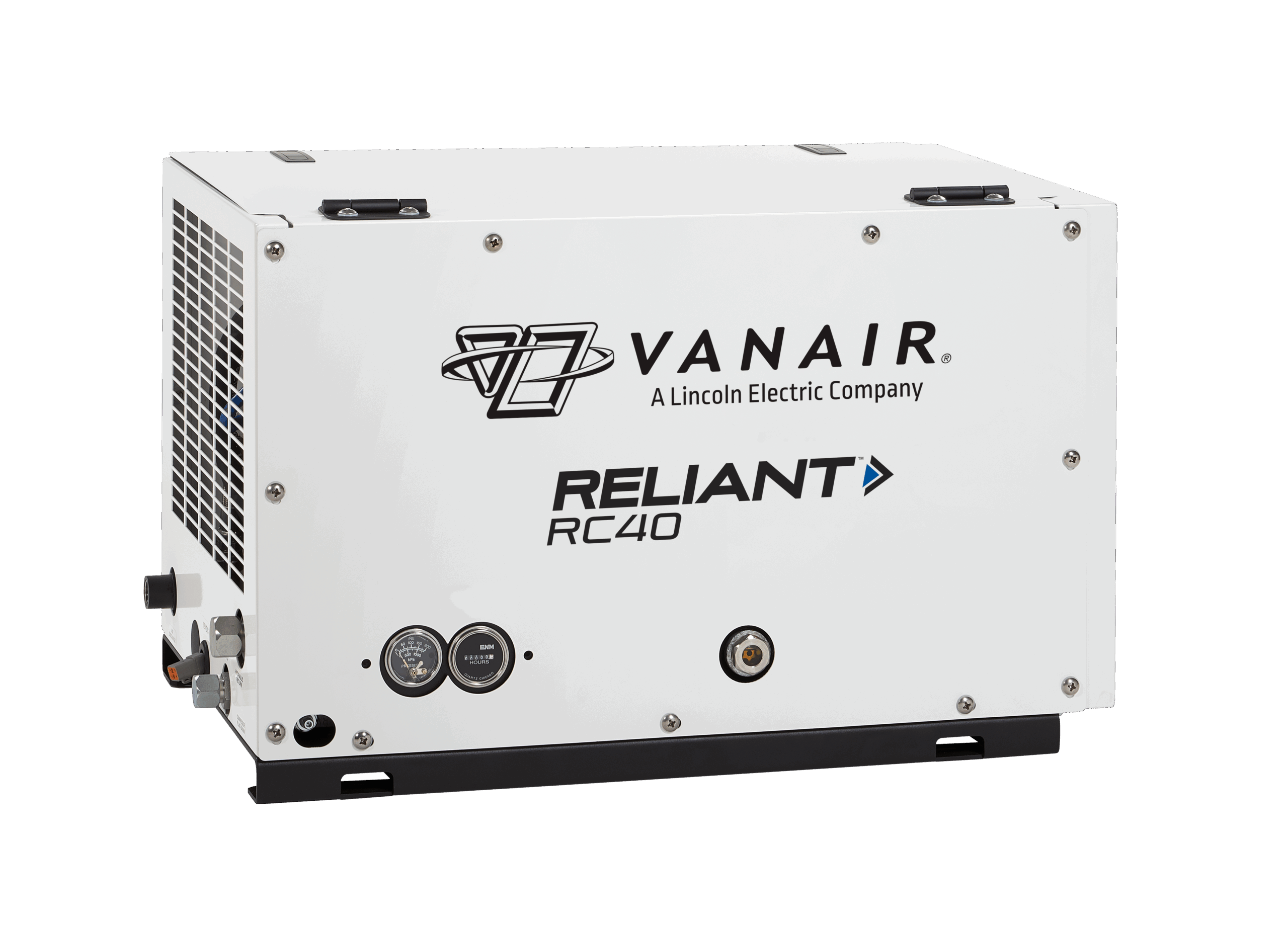

Providing a full 40 CFM of air at up to 175 PSI, the Reliant™ RC40 provides you with the most CFM for the cost in the market. Reliable and field-proven, the RC40 has been the go-to hydraulic driven reciprocating air compressor for mechanic and service technicians for over 10 years. Featuring an integrated cold weather package that will work in any type of climate, the RC40 has been designed to provide flexible mounting configurations and easy maintenance.

Reliant™ RC40 Hydraulically Driven Reciprocating Air Compressor

| Capacity (CFM) | Air Pressure (PSI) | Hydraulic Flow (GPM)* | Hydraulic Pressure (PSI)* |

|---|---|---|---|

| 30 | 100 | 9.5 | 1775 |

| 30 | 125 | 9.5 | 1875 |

| 30 | 150 | 9.5 | 2100 |

| 30 | 175 | 9.5 | 2200 |

| 40 | 100 | 12 | 1950 |

| 40 | 125 | 12 | 2070 |

| 40 | 150 | 12 | 2175 |

| 40 | 175 | 12 | 2275 |

Compressor Dimensions with Fittings (In.) – 37.0 L x 21.0 W x 22.0 H

Dry Weight (Lbs.) – 408

Dimensions listed are not a complete representation of total space necessary. Please consult Vanair® for overall space and air requirements.

*Ratings are approximate and are based on 120˚F hydraulic fluid temperature. Add 400 PSI minimum to hydraulic requirements for hydraulic system continuous pressure ratings. Reliant™ RC40 hydraulic relief valve is set at 3200 PSI. Consult Vanair® for specific details.

Product improvement is a continuing goal. Design and specifications are subject to change without notice or obligation.

- 051304 — Reliant™ RC40 – Reciprocating, 40 CFM, Open Center with Cold Weather*

- 051372 — Reliant™ RC40 – Reciprocating, 40 CFM, Open Center Standard*

*Models also available in 24V DC and closed center. Contact Vanair® Customer Service.

| Part Description | Part Number |

|---|---|

| RELIANT™ RC40 Air Filter Element Replacement Kit | KIT1090 |

| RELIANT™ RC40 and RC40-L Initial 50 Hour Compressor Maintenance Kit | KIT1091 |

| RELIANT™ RC40 Every 500 Hour or Annual Compressor Maintenance Kit | KIT1185 |

| 1 Gallon of Vanguard™ Reciprocating Compressor Oil | 271856-1GAL |

| Compressor Air Filter Element Only | 267833 |

| Air Reservoir Tank – 28 Gallons | 032707 |

| Air Reservoir Tank – 14 Gallon | 032708 |

| Filter Lubricator Regulator (FLR) 1/2” | 264493 |

| Moisture Separator | 265243 |

| Vibration Isolator Kit – 1/2” | KIT1202-001 |

| Air Reservoir Tank – 30 Gallons | OA49645 |

PERFORMANCE/FEATURES

- 30-40 CFM and Up to 175 PSI

- Open Center or Closed Center Hydraulic Manifold Block

- Vibration Isolation on Air Compressor and Drive System for Quiet Operation

- Four-Pin Weatherproof Electrical Connection

RECIPROCATING AIR COMPRESSOR

- Rugged, Cast Iron Crankcase

- Corrosion-Resistant Steel Valves

- Tapered Roller Type Main Bearings

- Balanced Crankshaft

- Weight-Matched Balanced Pistons

- High Flow Valves

- Lightweight Connecting Rods

AIR COMPRESSOR CONTROL SYSTEM

-

3-in-1 Air Compressor Manifold for Less Potential Leak Points

HYDRAULICS

- Air pressure Relief Safety Valve and Automatic Blow Down on Shut Down

- Hydraulic Oil Pressure Relief Valve

- Hydraulic Motor with Oil Outlet Check Valve

COLD WEATHER PACKAGE (OPTIONAL)

- Integrated System with Thermal Valve

INSTRUMENTATION

- Analog Hour and Pressure Gauges

-

Flexible Gauge Placement for Best Configuration on Your Vehicle

CANOPY

-

Flexible Mounting Options for the Hinge on the Hood for Best Opening Configuration

-

Attachment Free Panels for Easy Removal and Maintenance Work

-

Heavy-Duty Powder-Coated, Galvanneal Sheet Metal Enclosure

SAFETY EQUIPMENT

- Air Pressure Relief Safety Valve

- Hydraulic Oil Pressure Relief Valve

- Automatic Blow-Down on Shutdown

- 20 – 60 Gallon Air Reservoirs

- Aftercoolers

- Air Hoses

- Air Tools

- Cold Weather Package to Prevent Freeze-Ups

- Hose Reels and Fittings

- OSHA Excess Flow Safety Valve (Velocity Fuse)

- OSHA Excess Flow Safety Valve (Velocity Fuse)

- Service/Control Line Moisture Separators

- Tool Oiler/Lubricator

- Service Airline De-Icer

- Filter Lubricator Regulator (FLR) 1”

- 24V Converter

All hydraulic ratings and pressures are at the machine and do not take into account the pressure drops of individual hydraulic systems. These pressure drops need to be taken into account and added to the rating of the hydraulic pump and components. Vanair® highly recommends consulting a hydraulic supply expert for specifying the correct hydraulic pump size and type, oil reservoir size, hydraulic cooler, hydraulic pressure relief, and other hydraulic supply components for your application. Please take into consideration the following: The hydraulic flow and pressure requirements of the air compressor, the continuous hydraulic load when the compressor is running, the duty cycle and ambient operating temperatures, and any other hydraulic equipment that may share the same hydraulic supply system (Vanair® recommends a dedicated pump and hydraulic circuit).

For more information please consult Vanair®.