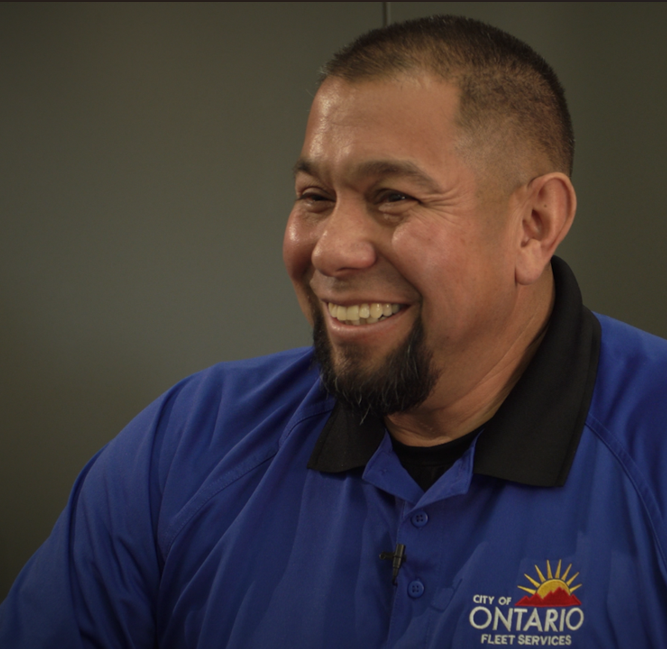

Interview with Gary Lara, Fleet Supervisor for the City of Ontario, CA

Searching for a system for your fleet that can minimize downtime, while also receiving exceptional support? See what Gary has to say to fleet managers considering a Vanair® PTO Shaft Driven Underdeck System.

Question: What is your main role as a fleet supervisor?

Answer: I’d say the major role that I play as a fleet supervisor is to listen to our customers’ concerns. I have to minimize our downtime, keep vehicles running, and at the same time… look professional out in the field.

Q: What has made you confident in using Vanair’s PTO Underdeck Systems for your fleet?

A: I believe that confidence really came from the training and understanding how to operate the system, and then also having availability to pick up the phone and Vanair® can answer any of our questions and still help us out through any troubleshooting needs that we may have.

Q: How has Vanair® impacted your fleet?

A: Vanair® provided resources available to us in a timely manner, which means truck uptime. I appreciate all the services that you have given us in order to build this confidence in our team.

—

Utilizing the truck’s own engine for power, Vanair® PTO Driven Underdeck Rotary Screw Compressor Systems provide the power your crew needs to get the job done where and when they need it. Using a single PTO opening and the truck’s own engine for power, these systems provide impressive air power, AC power or hydraulics, or any combination of all three, and more. These assemblies mount out of sight under your vehicle. This leaves the towing hitch free for other equipment and opens up the truck bed for additional storage space. Vanair® PTO Underdeck Systems support a wide variety of field applications, including pneumatic tools for post pounding, pipe fusion, sewer relining, gas line charging, and more.