From municipalities to telecommunications, trenchless technology plays an indispensable role in effectively applying or upgrading underground pipes, cables, etc. Moreover, these technologies are a viable solution. They prevent the need to entirely disrupt surface ground and still work on a long stretch of pipelines, cables, or conduit. Compressed air is a vital source in powering these trenchless technologies. Operators can rely on Vanair® PTO Driven Underdeck Systems as a source for powerful compressed air for various trenchless applications, all while maximizing truck space and reducing vehicle weight. Vanair® underdeck systems can support:

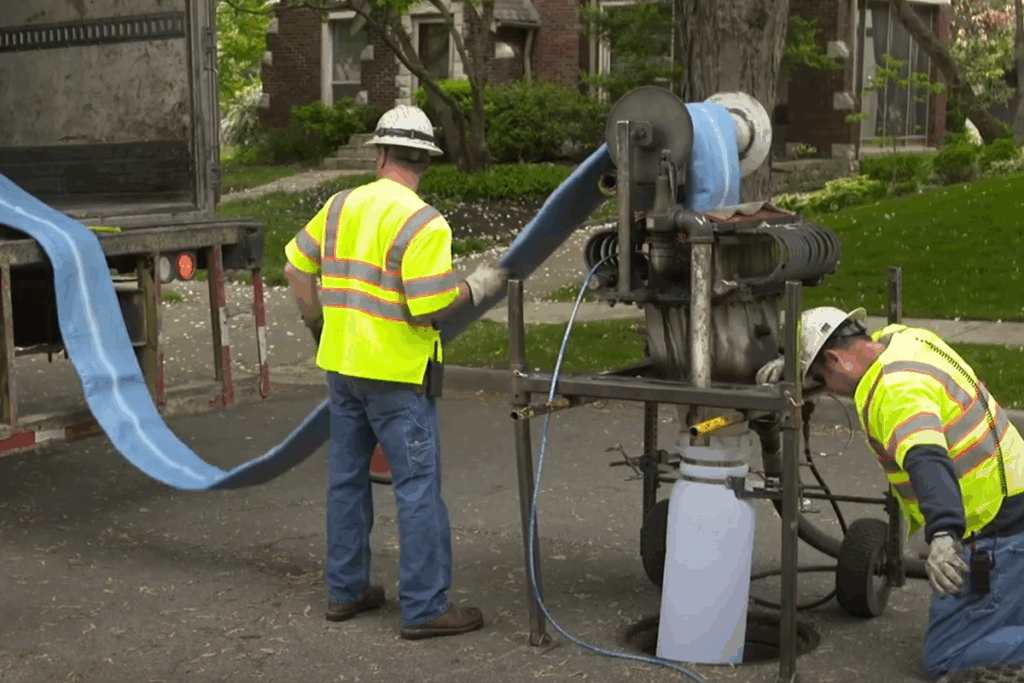

Cured-in-place pipe (CIPP)

- CIPP is a method of inserting a membrane into an old pipeline and inflating it with compressed air to replace and/or repair the old pipe. This method repairs damaged sections of pipe to replace an entire pipeline, for preventive maintenance, or to address any structural issues.

Fiberoptic cable blowing

- The increased demand for fiber optic cable installation requires reliable compressed air to insert cable through long distances underground. This method requires compressed air to push the fiber cable through the underground ductwork.

Horizontal directional drilling (HDD)

- This trenchless method is used to install underground pipelines, conduits, and cables along curved paths. Compressed air plays a key role in this method. It powers pneumatic hammers or flush debris from the borehole created in the process.

Pipe bursting

- Pipe bursting pulls a bursting tool to insert and expand into an old pipe to break it apart and replace it with new pipe. The fragments of the old pipe are pushed and left in the underground soil. Compressed air plays a key role in powering the percussive tool that breaks apart the old pipe.

Whether your crew is installing fiber optic cables or upgrading sewer lines, these trenchless technologies are reliable solutions for efficiency. Systems such as Vanair® PTO Driven Underdeck Systems are a reliable, space-saving solution to power pneumatic tools and more to support trenchless applications. These underdeck systems not only enhance productivity but also reduce costs. With exclusive innovations designed to keep operations running smoothly, they help minimize downtime, maximize performance, and provide lifelong cost savings.